- Pre Painted Long Span Roofing

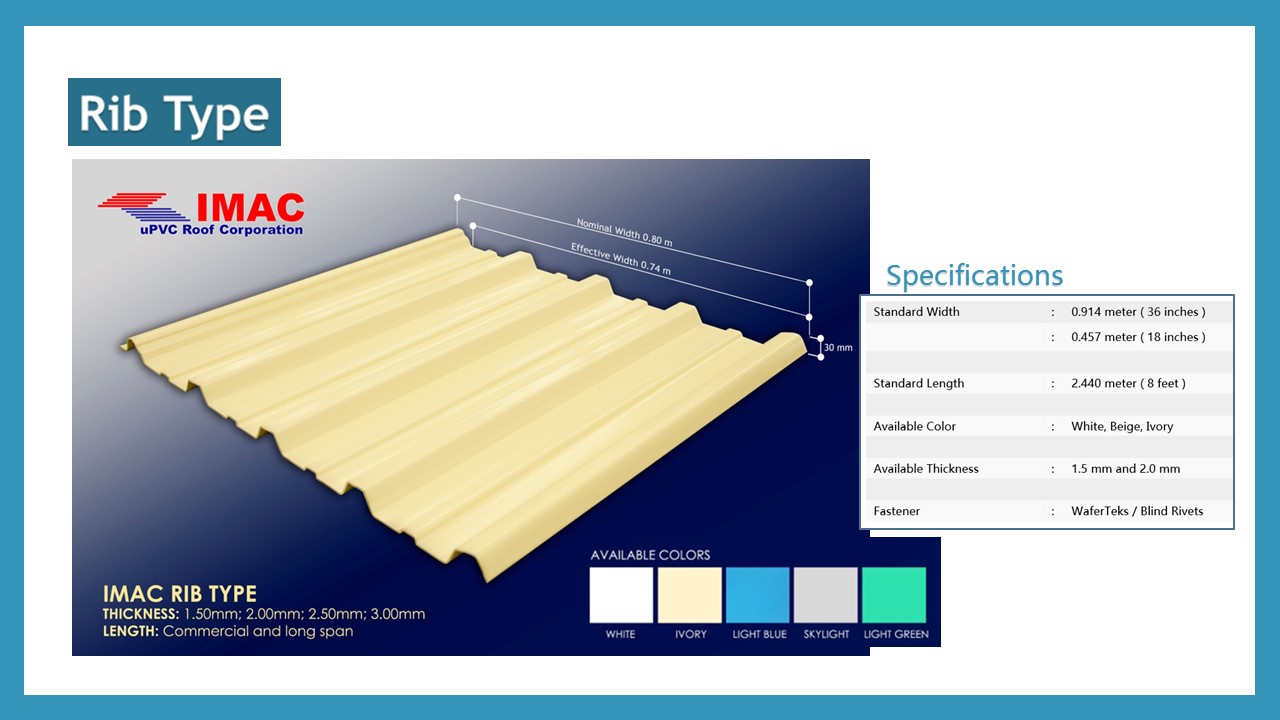

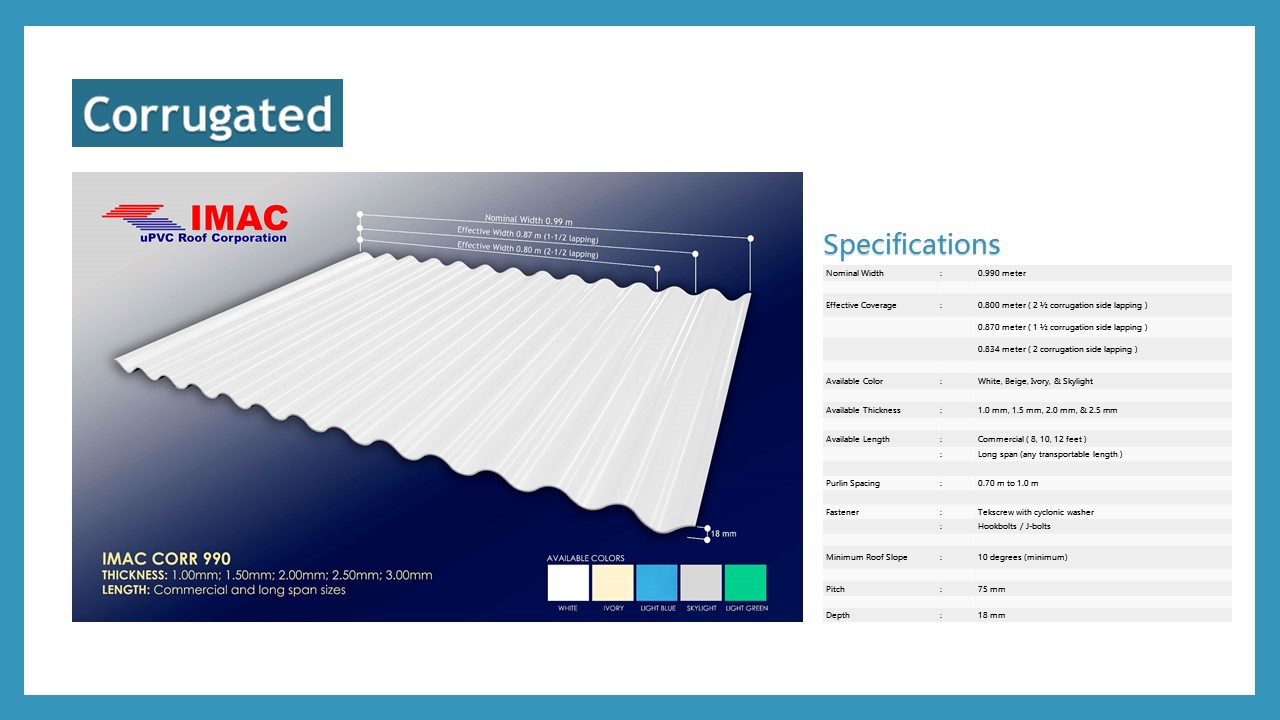

- uPVC Thermoplastic Roofing

- Steel Decking

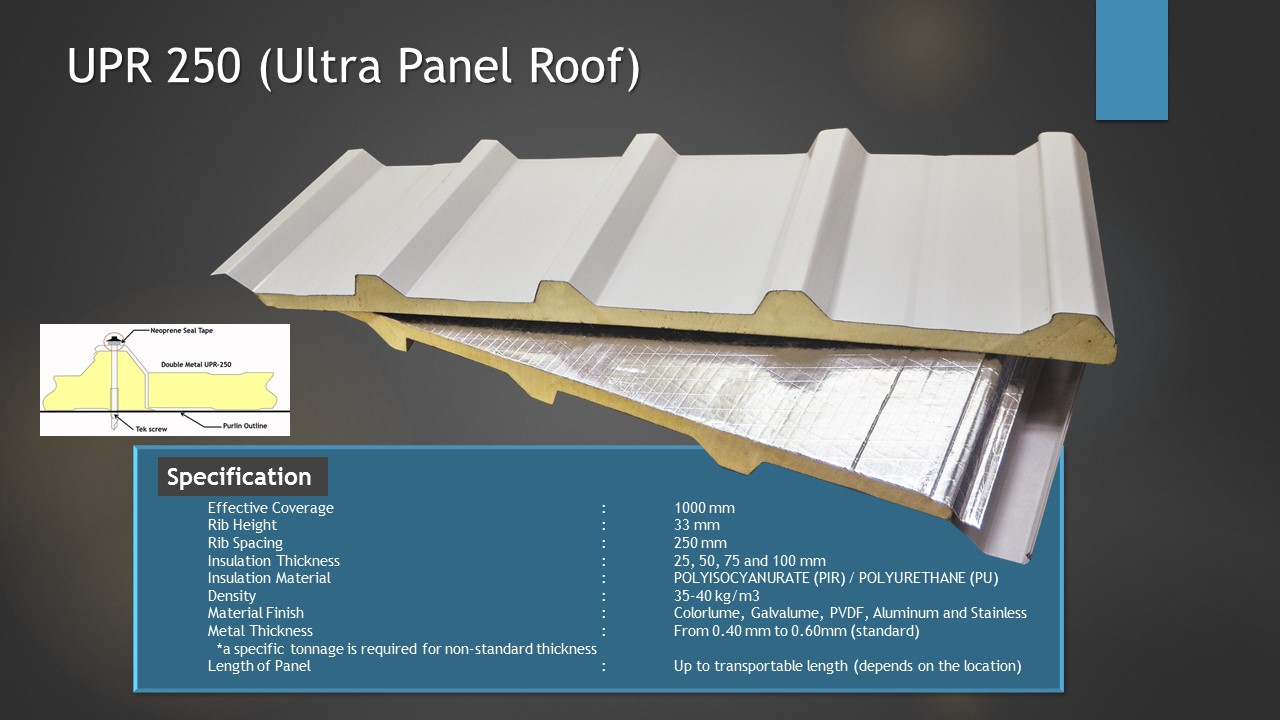

- UPR (Pre Insulated Roof Panel)

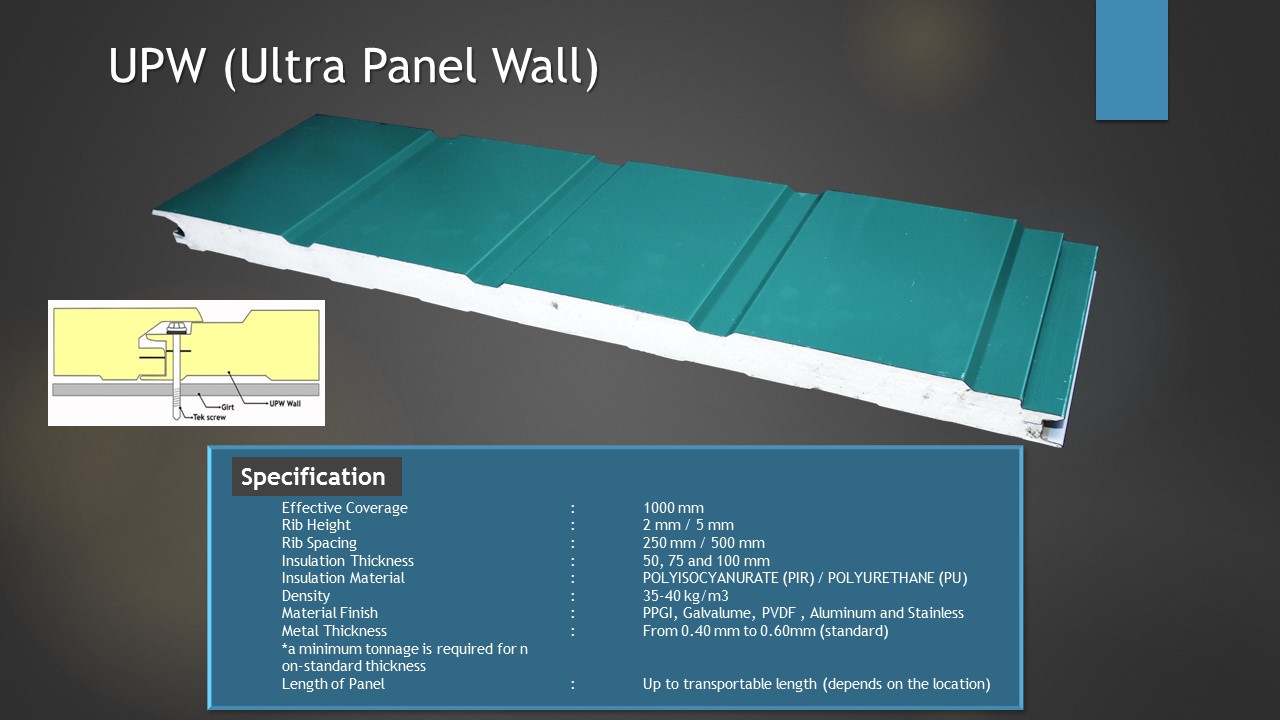

- UPW (Pre Insulated Wall Panel)

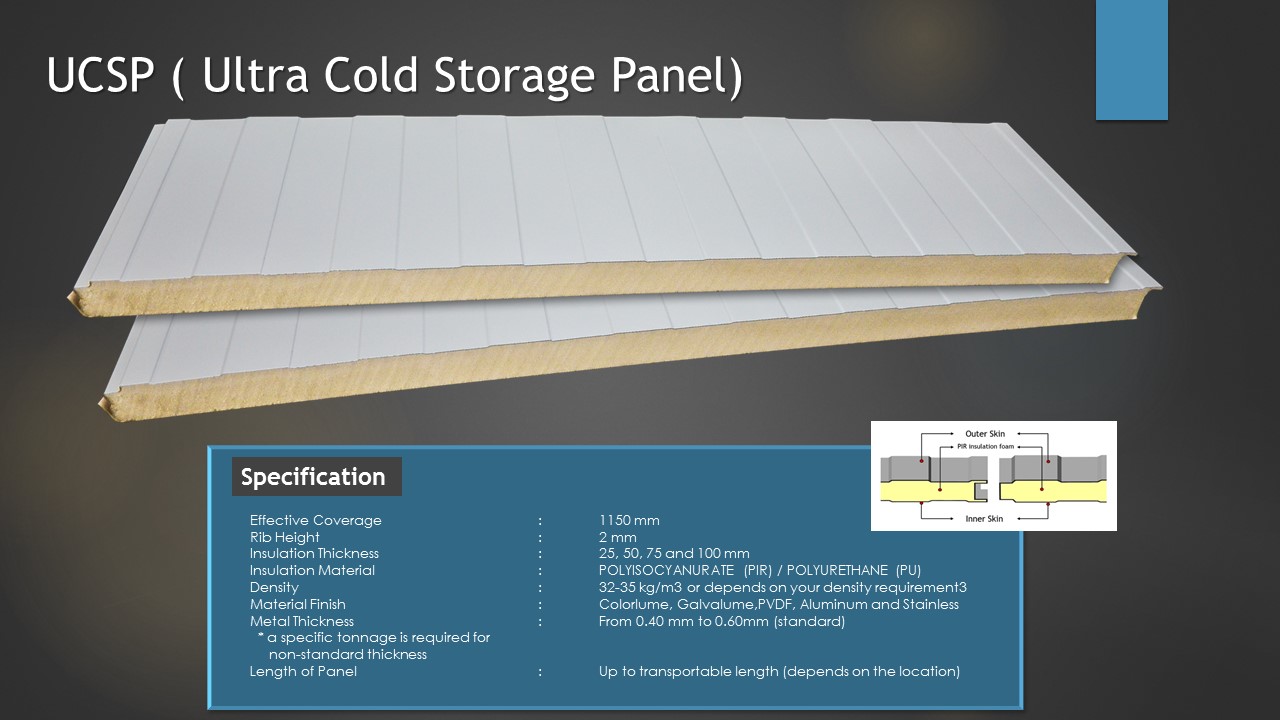

- USCP (Cold Storage Panel)

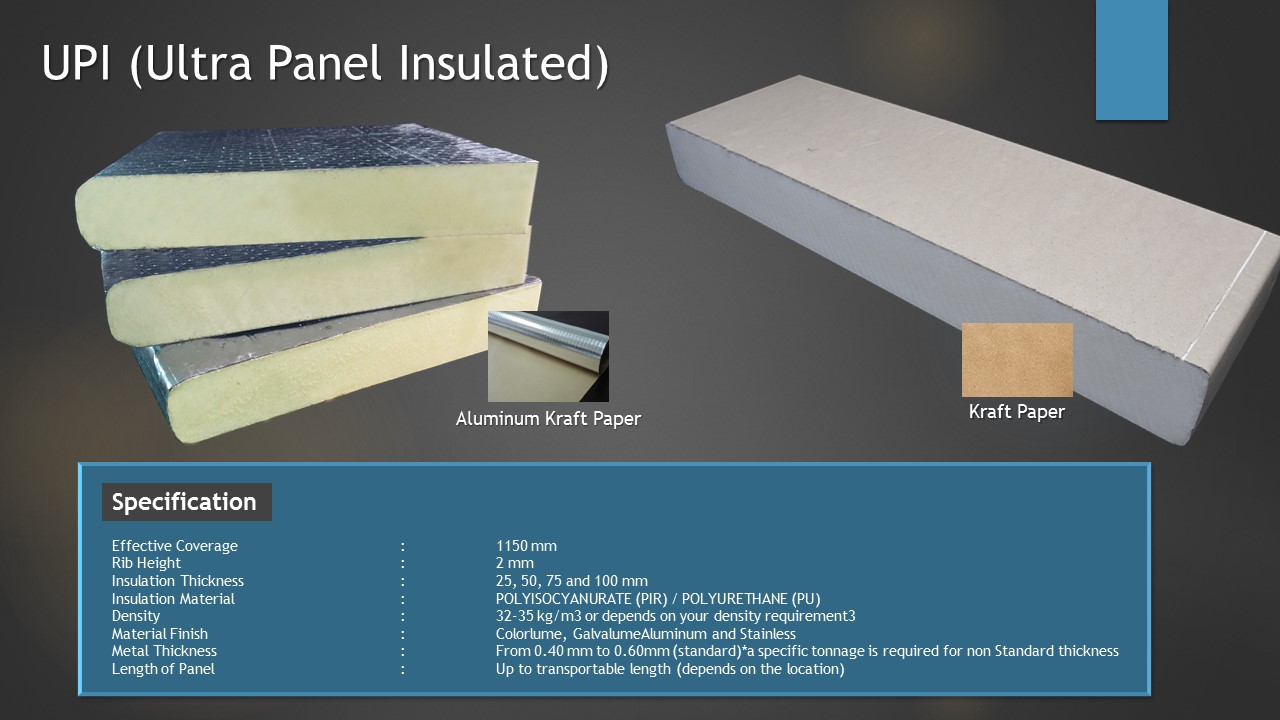

- UPI (Insulated Board)

- Cold Storage System

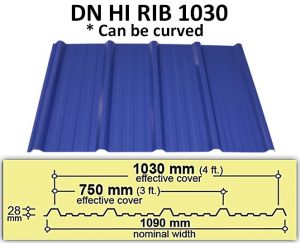

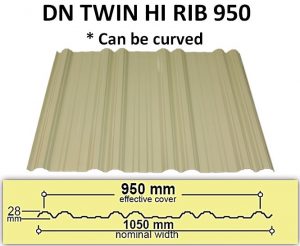

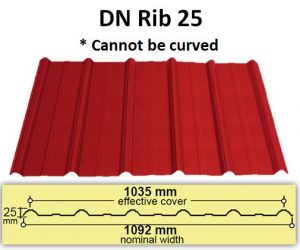

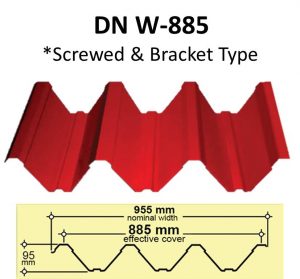

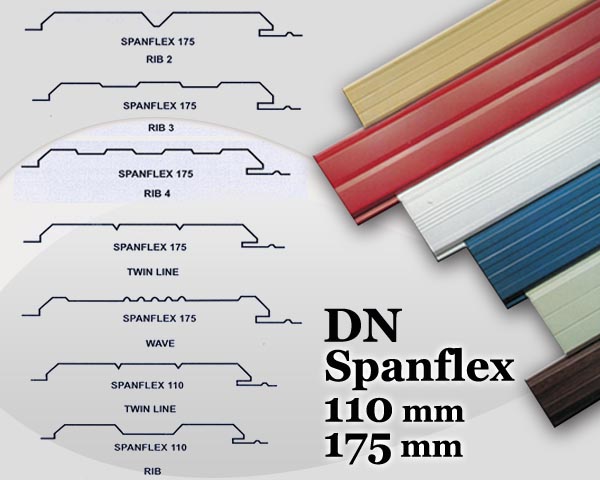

STANDARD ROOF PROFILES: STRAIGHT & CURVED

STANDARD ROOF PROFILES: STRAIGHT & CURVED

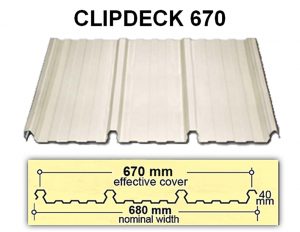

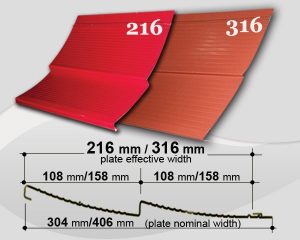

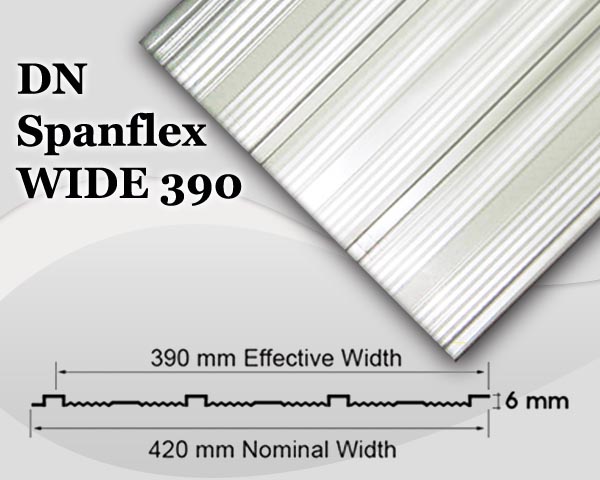

CONCEALED & DEEP PROFILES FOR LOW SLOPE ROOFING

CONCEALED & DEEP PROFILES FOR LOW SLOPE ROOFING

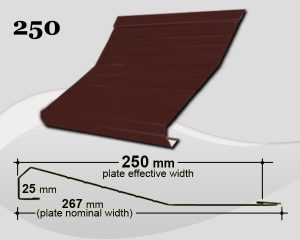

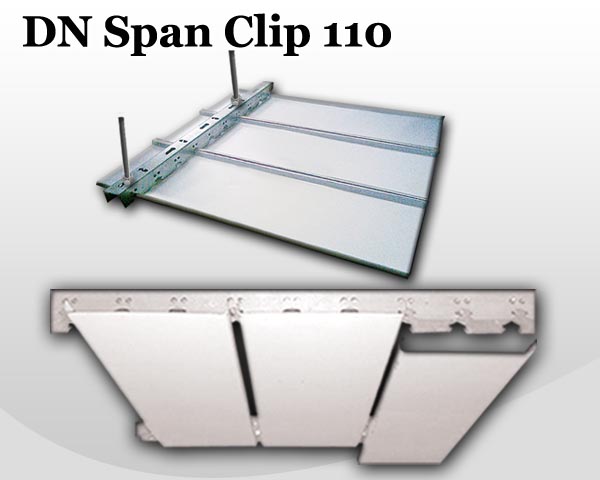

HORIZONTAL ROOF

HORIZONTAL ROOF

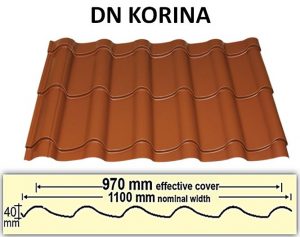

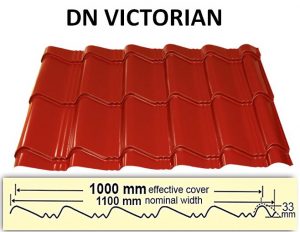

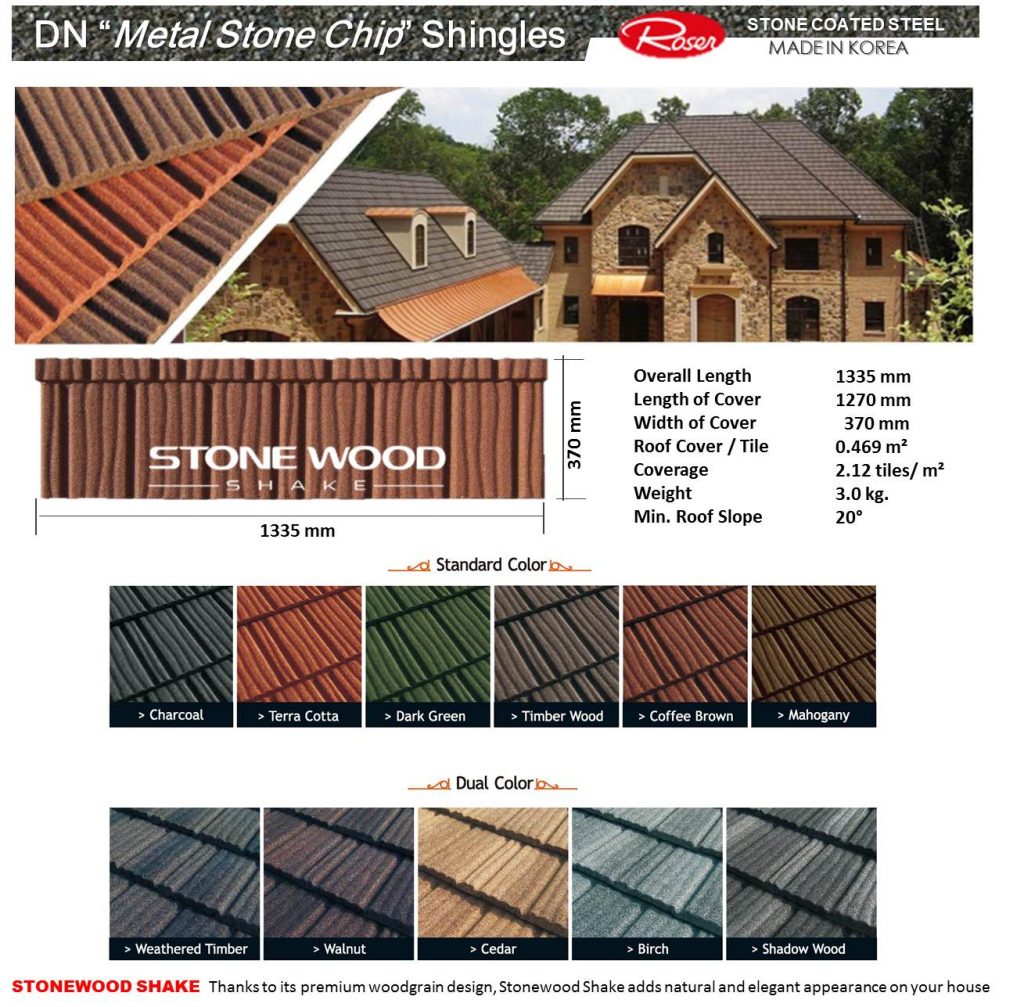

TILE ROOF

TILE ROOF

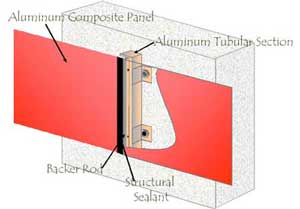

Aluminum Composite Panel

Aluminum Composite Panel

It has a high degree of levelness to preserve the fine architectural design ans can be roller bended to suit various design shapes.

| Thickness : | 3 mm |

| 4 mm | |

| 5 mm | |

| Coating : | Polyester |

| PVDF (Polyvinynilidine Flouride) | |

| PVDF (Polyvinynilidine Flouride) + NANO |

APPLICATIONS:

- Interior & Exterior material of building

- Structure of exhibit hall

- Advertisement boards

- Factory Buildings

- Bath, washroom & simple frame wall, etc.

- Cladding of buildings situated in a highly corrosive environment. ( e.g. project near the seashore)

General Properties

| Testing Item | Standard | Result |

|---|---|---|

| Unit weight | ASTM D792 | t3mm=4.6kg/m2 t4mm=5.5kg/m2 |

| Outdoor temperature resistance | ASTM D1654 | No abnormity |

| Thermal expansion | ASTM D696 | 3.0×10-5 -1 |

| Thermal deformation temperature | ASTM D648 | 115 |

| Thermal conduction | ASTM 976 | 0.102Kcal/m.hr |

| Flexural rigidity | ASTM C393 | 14.0×105 |

| Impact resistance | ASTM D732 | 1.650kgf |

| Adhesive strength | ASTM D903 | 0.74kgf/mm |

| Sound-insulating rate | ASTM E413 | 29 |

| Flexural Elasticity | ASTM D790 | 4055kg/mm2 |

| Shear resistance | ASTM D732 | 2.6kgf/mm2 |

| Minimum bending radius | ASTM D790 | 45mm 70mm |

| Fire propagation | ASTM E84 | Qualified |

| Smoke developed | ASTM E84 | <45 |

| Wind-pressure resistance | ASTM E330 | Passed |

| Properties against water | ASTM E331 | Passed |

| Properties against air | ASTM E283 | Passed |

PVDF Coating Finish

| Testing Item | Standard | Result |

|---|---|---|

| Finish coat thickness | ISO 2360(CNS 8406)º | 27.6m |

| Gloss | ASTM D532-89 | 20~45% |

| Pencil hardness | ASTM D3363-00 | 2H |

| Toughness | ASTM D4145-83 | 2T no rift |

| Adhesive force | ASTM 3359-97 | 4B |

| Impact resistance | ASTM D2794-93 | >100kg.cm |

| Abrasion resistance | ASTM D968-93 | 64.6 L/mil |

| Mortar resistance | ASTM 605.2-90 | 24 Hrs pat test exceed |

| Humidity resistance | ASTM D714-97 | 3000hr No blister |

| ASTM D2247-02 | ||

| Boiling-water resistance | ASTM D3359-B | Passed |

| Salt-spray resistance | ASTM D117-03 | 3000hr No blister |

| Acid resistance | ASTM D1308-87 | No Effect |

| AAMA 605.2-91,TEST#7,7.31 | ||

| Alkali resistance | ASTM D1308-87 | Passed |

| Solvent resistance | ASTM D2248-73 | Passed |

| ECCA T5&NCCA NO.11-18 | ||

| Color retention | ASTM D2244-93 | E=0.34 |

| Chalk resistance | ASTM D4214-98 | No Chalking |

| Gloss retention | ASTM D2244-93 | 84.20% |

Color Chart

Characteristics of Aluminum Composite Panel

Lightweight

ACP only weighs 5.6kg/m2. Definitely lighter than other cladding materials such as granite and marble. It can reduce structure members.

Durability

Aluminum Composite Panel is highly resistant to chemical corrosion due to the advance Fluoroplastic coating of polyvinilydine fluoride (PVDF), the composite material is rigid, resistant to blows, breakage and pressure and has a high bending and breaking strength.

Flatness

As the composite material is rigid, the flat surface be preserved. This is considered a major advantage of ACP.

Fire Resistance

ACP are laminated at the temperatures from 200 °C to 250 °C to bond the aluminum sheets to the PE Core. The non-flammable cover sheets protect the plastic core.

Material Composition

ARCHITECKS panel is painted with an advance fluorocarbon paint (PVDF) a durable coating on Aluminum laminated composite material. The laminated structure of ACP ensures exceptional strength of the panel.

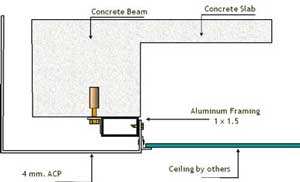

Horizontal Section

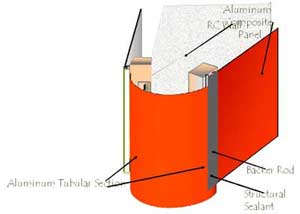

Round Section

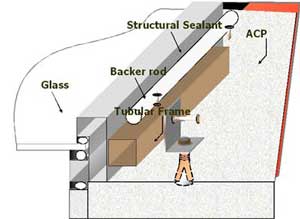

Panel and Window Section

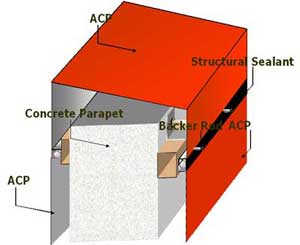

Coping Section

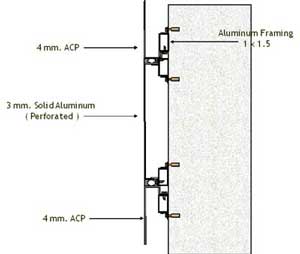

Connection of Perforated Panel

Connection of ACP to Ceiling

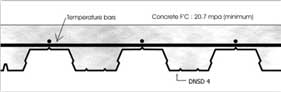

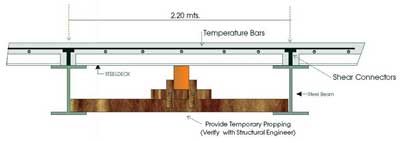

Concrete Floor Steel Decking

Concrete Floor Steel Decking

It is used to support concrete of a Concrete Slab. It was developed to provide a structurally efficient product for use in floor systems.

It is designed to create a permanent formwork that replaced the conventional wood forms that are used in Hanging Slabs.

Despite the fact that it is a structural component, its uniform quality can offer an attractive appearance, especially with the use of properly specified shop and field applied coatings.

Steel deck is also a component of many UL and ULC approved fire rated assemblies.

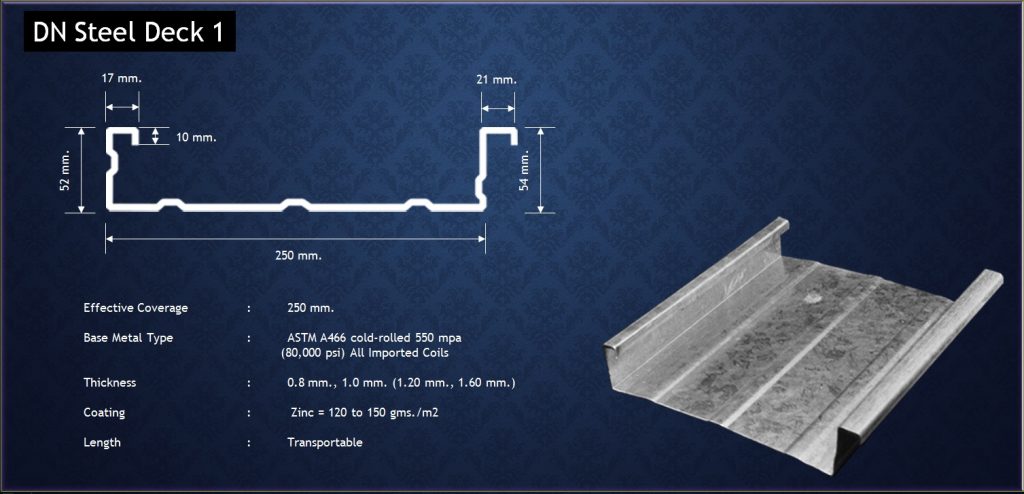

Specifications

| Base metal type | : | ASTM A466 cold-rolled 550 mpa (80,000 psi) (Available in Local & Imported coils) Now available in prepainted for Steel Deck One |

||

| Thickness | : | 0.80 mm | ||

| 1.00 mm | ||||

| 1.20 mm | ||||

| 1.60 mm | ||||

| Coating | : | Imported Coil – Zinc = 275 gms / m2 | ||

| Local Coil – Zinc = 120 to 150 gms / m2 | ||||

| Length | : | Transportable |

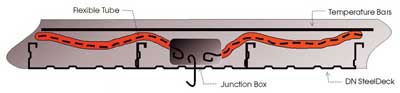

Propping and Electrical Layout

Electrical Layout

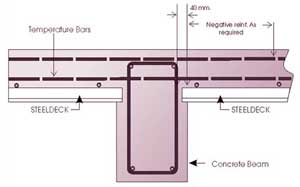

Connection Details

Typical Interior Support

Typical Interior Support

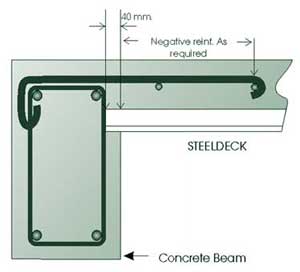

Typical Sprandel End

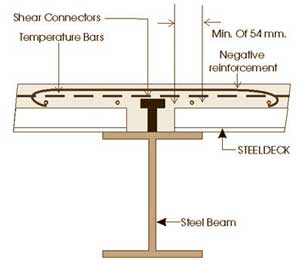

Composite Construction

COMPOSITE CONSTRUCTION

All reinforced concrete are composite construction in the sense that they combine two dissimilar material in any structural member. The term composite is usually applies to the combination of the concrete with structural steel in the form of DN Steel Deck Panels. The structural steel, while capable of carry loads when acting alone can develop much strength and stiffness if it acts integrally with the concrete.

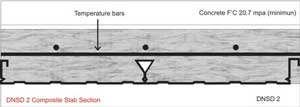

DN STEEL DECK REINFORCED COMPOSITE SLABS

Floor and slabs, incorporating cold formed DN Steel Deck Panels, which servers both as form and reinforcement for the concrete placed over them, are widely use in the building where the main framing is either steel or composite construction. DN steel deck has a base metal of ASTM 446 cold rolled, 550 mPa (80,000 psi) yield strength and available thickness of 0.80 mm, 1.0 mm and 1.2 mm with zinc coating of Z-27.

DN Steel Decking, easily and quickly laid on a steel floor beams, serves as working flatform to support construction activities and to carry freshly poured concrete. This eliminates the need of temporary flaseworks and forms.

Reinforced Composite Slabs

COMPOSITE CONSTRUCTION

All reinforced concrete are composite construction in the sense that they combine two dissimilar material in any structural member. The term composite is usually applies to the combination of the concrete with structural steel in the form of DN Steel Deck Panels. The structural steel, while capable of carry loads when acting alone can develop much strength and stiffness if it acts integrally with the concrete.

DN STEEL DECK REINFORCED COMPOSITE SLABS

Floor and slabs, incorporating cold formed DN Steel Deck Panels, which servers both as form and reinforcement for the concrete placed over them, are widely use in the building where the main framing is either steel or composite construction. DN steel deck has a base metal of ASTM 446 cold rolled, 550 mPa (80,000 psi) yield strength and available thickness of 0.80 mm, 1.0 mm and 1.2 mm with zinc coating of Z-27.

DN Steel Decking, easily and quickly laid on a steel floor beams, serves as working flatform to support construction activities and to carry freshly poured concrete. This eliminates the need of temporary flaseworks and forms.

DECK ONE

| Steel Section Properites | ||||

| t (mm.) |

y (mm.) |

I (mm.mm) |

St (mm3) |

Sb (mm3) |

| 0.80 1.00 |

13.02 13.13 |

122046.73 151745.35 |

3300.29 4115.99 |

9374.25 11554.72 |

| Composite Section Properties | ||||||

| t (mm.) |

y (mm.) |

x (mm.) |

I (mm.mm) |

St (mm3) |

Sb (mm3) |

|

| 0.80 | 100 125 150 |

2901.60 | 34.80 40.68 45.96 |

11412549.66 20361085.33 32129244.80 |

327924.61 500491.83 699000.72 |

175045.44 241480.14 308829.74 |

| 1.00 | 100 125 150 |

3627.00 | 37.75 44.28 50.16 |

13233160.46 23803316.49 37785304.16 |

350536.32 537523.02 753310.42 |

212584.93 294899.68 378454.82 |

| Maximum allowable superimposed load (80,000 psi) design for 33,000 psi tensile strength is also available |

|||||||||

| I (mm.) |

Maximum allowable superimposed load, kPa | ||||||||

| span (m) | |||||||||

| 1.50 | 1.80 | 2.00 | 2.30 | 2.50 | 2.80 | 3.00 | 3.50 | ||

| 0.80 | 100 125 150 |

12.00 12.00 12.00 |

12.00 12.00 12.00 |

12.00 12.00 12.00 |

12.00 12.00 12.00 |

12.00 12.00 12.00 |

10.01 12.00 12.00 |

8.41 12.00 12.00 |

4.88 9.14 12.00 |

| 1.00 | 100 125 150 |

12.00 12.00 12.00 |

12.00 12.00 12.00 |

12.00 12.00 12.00 |

12.00 12.00 12.00 |

10.85 12.00 12.00 |

9.13 12.00 12.00 |

6.02 10.01 12.00 |

|

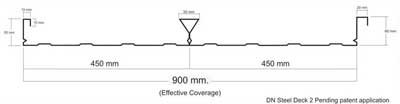

DECK TWO

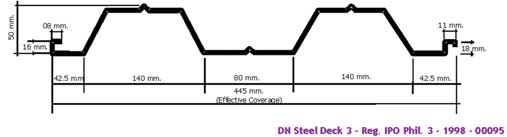

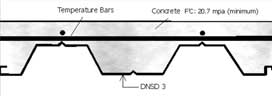

DECK THREE

| Steel Section Properites | |||||

| t (mm.) |

W (kg/mm.) |

A (mm2/mm) |

I (mm4/mm) |

St (mm3) |

Sb (mm3) |

| 0.80 1.00 1.20 1.40 1.60 |

8 10 12 14 16 |

1.083 1.353 1.624 1.895 2.165 |

401.477 515.760 639.319 774.008 921.684 |

19.915 25.583 31.712 38.393 45.718 |

13.454 17.284 21.425 25.939 30.888 |

| Maximum allowable superimposed load .Kpa | |||||||||

| I (mm.) |

Slab DEPTH (MM.) |

span (m) | |||||||

| 1.50 | 1.80 | 2.00 | 2.30 | 2.50 | 2.80 | 3.00 | 3.50 | ||

| 0.80 | 100 125 150 |

19.20 19.20 19.20 |

19.20 19.20 19.20 |

15.95 19.20 19.20 |

12.70 17.69 19.20 |

9.73 13.57 17.60 |

7.48 10.45 13.58 |

6.35 8.88 11.55 |

4.31 6.05 7.90 |

| 1.00 | 100 125 150 |

19.20 19.20 19.20 |

19.20 19.20 19.20 |

15.10 19.20 19.20 |

15.10 19.20 19.20 |

11.62 16.48 19.20 |

8.99 12.78 16.77 |

7.66 10.90 14.32 |

4.91 7.54 9.93 |

| 1.20 | 100 125 150 |

19.20 19.20 19.20 |

19.20 19.20 19.20 |

18.97 19.20 19.20 |

18.97 19.20 19.20 |

14.67 19.20 19.20 |

10.54 15.95 19.20 |

3.57 13.67 17.79 |

5.40 9.57 12.48 |

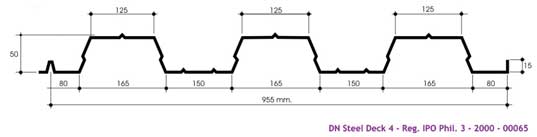

DECK FOUR

| Deck Properites | ||||||||

| Gauge | t (mm.) |

W (kg.m2 |

A mm2/mm |

I mm4/mm |

Sp mm2/mm |

Sn mm2/mm |

Rb kN/m |

oVn kN/m |

| 22 | 0.8 | 8 | 1.021 | 518 | 23.4 | 18.6 | 11.929 | 27.88 |

| 20 | 1.0 | 10 | 1.276 | 648 | 29.2 | 23.3 | 16.995 | 33.76 |

| 18 | 1.2 | 12 | 1.532 | 777 | 35.1 | 27.9 | 28.779 | 44.55 |

| 16 | 1.6 | 16 | 2.042 | 1037 | 46.8 | 37.2 | 42.778 | 55.9 |

| Composite Properties | |||||||||

| t mm. |

Slab Depth mm. |

OM kN.m. |

A m2/m. |

Vol M2/m2 |

W kN/m2 |

Sc mm3/m |

Iave mm4/m |

oM kN.m |

oV kN/m |

| 0.80 | 100 125 150 180 |

16.68 22.64 28.61 35.77 |

0.059 0.079 0.099 0.126 |

0.077 0.102 0.127 0.157 |

1.815 2.402 2.990 3.695 |

54507 75372 97490 124960 |

5792014 11151680 18953266 32128000 |

12.47 17.62 22.79 29.21 |

38.312 50.410 62.853 72.245 |

| 1.00 | 100 125 150 180 |

20.25 27.70 35.16 44.11 |

0.059 0.079 0.099 0.126 |

0.077 0.102 0.127 0.157 |

1.815 2.402 2.990 3.695 |

66653 92341 119684 153720 |

6312754 12066492 20408851 34432764 |

15.58 21.59 27.98 35.93 |

38.312 50.410 63.517 78.125 |

| 1.20 | 100 125 150 180 |

23.59 32.54 41.50 52.24 |

0.059 0.079 0.099 0.126 |

0.077 0.102 0.127 0.157 |

1.815 2.402 2.990 3.695 |

78488 108910 141414 181962 |

6800543 12924654 21779514 36613265 |

18.35 25.46 33.06 42.53 |

38.312 50.410 63.517 80.576 |

| 1.60 | 100 125 150 180 |

29.54 41.48 53.41 67.73 |

0.059 0.079 0.099 0.126 |

0.077 0.102 0.127 0.157 |

1.815 2.402 2.990 3.695 |

101216 140773 183335 236641 |

7691422 14490994 24291105 40631191 |

23.66 32.91 42.89 55.32 |

38.312 50.41 63.517 80.576 |

| t (mm.) |

Slab Depth mm. |

OM kN.m. |

Uniforem Superimposed Loads, kn/m2 | ||||||

| span (m) | |||||||||

| 2.0m | 2.5m | 3.0m | 3.5m | 3.75m | 4.0m | 4.5m | |||

| 0.80 | 100 125 150 180 |

12.74 17.62 22.79 29.21 |

14.57 19.2 19.2 19.2 |

8.83 12.29 15.99 19.2 |

5.72 7.99 10.42 13.46 |

3.84 5.39 7.06 9.15 |

3.17 4.46 5.86 7.61 |

2.62 3.7 4.88 6.36 |

1.79 2.55 3.34 4.44 |

| 1.00 | 100 125 150 180 |

15.58 21.59 27.98 35.93 |

18.11 19.2 19.2 19.2 |

11.1 15.5 19.2 19.2 |

7.3 10.19 13.94 17.19 |

4.99 7.01 9.62 11.9 |

4.18 5.87 8.08 10.1 |

3.51 4.94 6.82 8.46 |

2.49 3.53 4.9 6.1 |

| 1.20 | 100 125 150 180 |

18.35 25.46 33.06 42.53 |

19.2 19.2 19.2 19.2 |

13.32 18.56 19.2 19.2 |

8.83 12.34 16.9 19.2 |

6.13 8.59 11.8 14.59 |

5.16 7.25 9.98 12.35 |

4.37 6.15 8.49 10.52 |

3.17 4.48 6.22 7.73 |

| 1.60 | 100 125 150 180 |

23.66 32.91 42.89 55.32 |

19.2 19.2 19.2 19.2 |

17.57 19.2 19.2 19.2 |

11.78 16.48 19.2 19.2 |

8.3 11.63 15.25 19.2 |

7.05 9.89 12.99 17.56 |

6.03 8.48 11.15 15.09 |

4.48 6.32 8.32 11.32 |

Purlins

Purlins

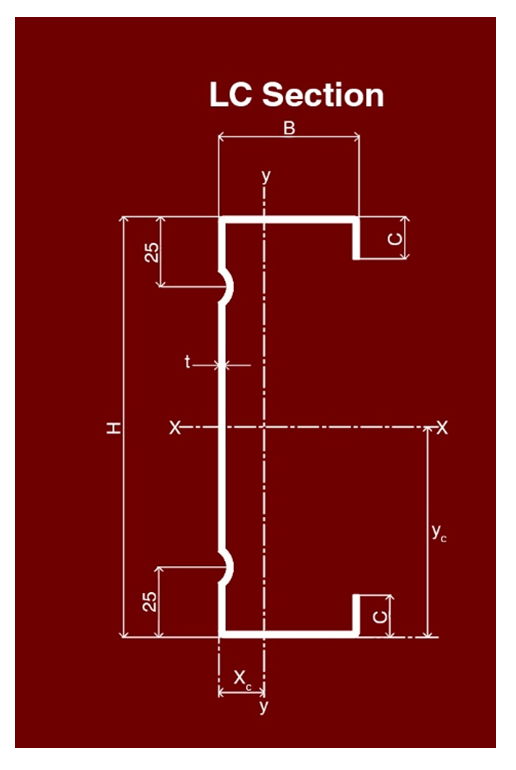

C Purlins

C Purlins are horizontal structures that are used to support the load from the roof or the sheathing. The plane surface of this purlin on one side has made it a preferred material for cladding due to its easy installation on concrete structures or steel. Our range purlins are light in weight and perfect for simple span construction.

- Optimum quality

- Easy installation

- Cut to size

- High tensile strength

- Abrasion & corrosion resistance

Advantages of C Purlins:

- Ability to span length

- Purlin erection is easier than others

- Fast to erect and easy handling

- No side drilling/cutting required

- Assured dimensions and straightness

- High durability, versatility and uniform quality

- Low transportation cost due to decreased weight

- Close tolerances on sectional sizes due to process of cold roll forming

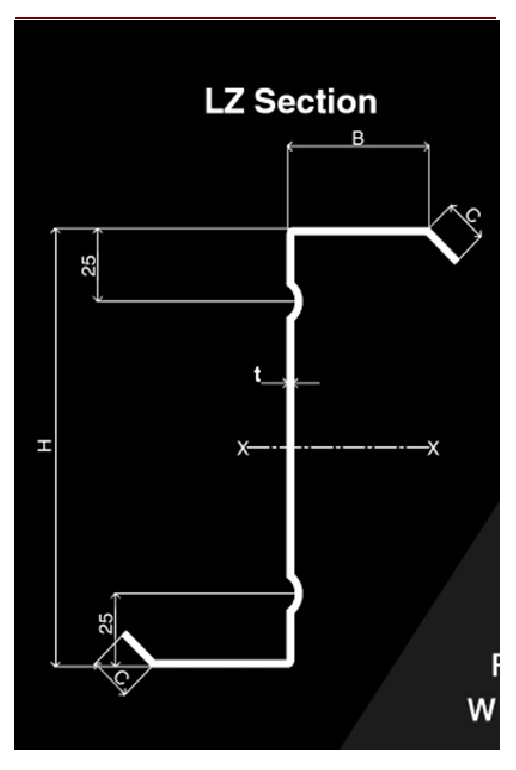

Z Purlins

Z Purlins are made using cold-formed or rolled sheets for supporting roof. The flexible shape of these beams facilitates various designs solutions. These purlins are extensively used in huge roofing solutions such as godowns, workshops, industrials sheds and many more. The range is known for saving upto 50% on structural sheet in comparison with hot rolled angles. Our purlins are crisp and clean in design and do not allow the scope of inaccurate lengths.

- Ability to span length

- Fast to erect and easy handling

- Assured dimensions and straightness

- Purlin erection is easier than others

- High durability, versatility and uniform quality

- Low transportation cost due to reduced weight

- Close tolerances on sectional dimensions owing to process of cold roll forming

- Saving up to 35-40% in weight and 20% in cost when compared to hot rolled purlins

Why use steel purlins?

- Steel is generally cheaper than wood construction

- Steel is recyclable and thus “greener” than wood

- Steel structures can be assembled quicker than wood

- Steel is lighter than wood structures of the same size

- Steel is not affected by termites or other insects that feed on wood

- Steel can be expected to last much longer than wood in most applications

- Steel has greater fire resistance than wood

Materials Specifications

- Hot-dipped zinc-coated steel

- Conforms to AS 1397/G275/G340

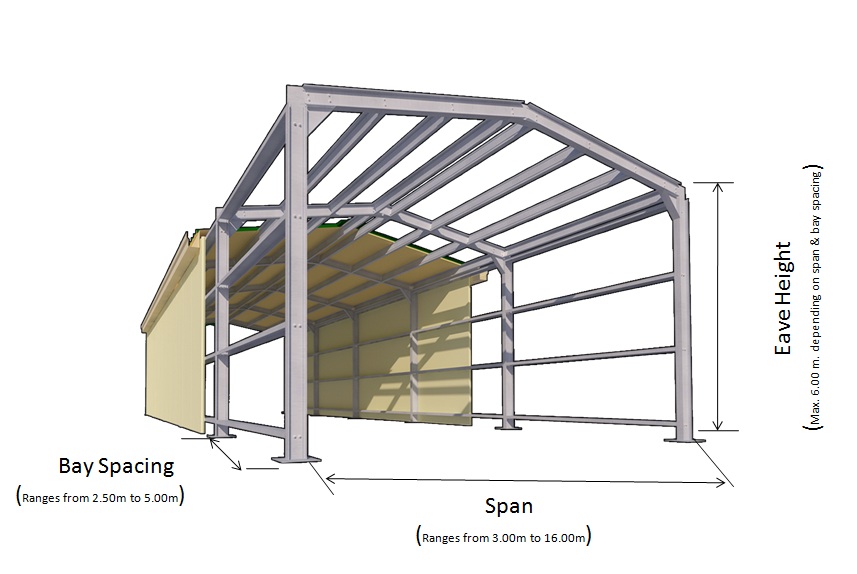

- SAVE ON THE COST OF BUILDING MATERIALS

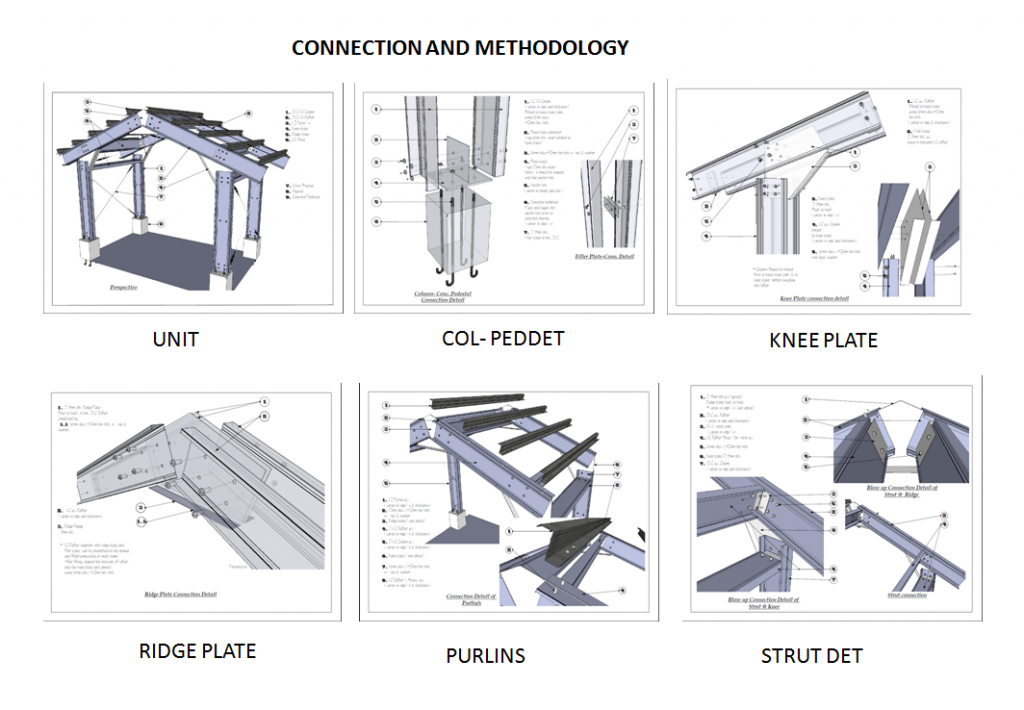

AISSI Pre – engineered Rigid Frame was developed to serve the needs of the building industry requiring structures with unsupported spans of not more than 16m width. Building dimensions of this type fall in the region where the use of conventional steel construction method, such as welding of rolled or built – up structural shapes, becomes uneconomical. With the use of hot- dipped, galvanized light gage steel for the primary members of the structure such as that of AISSI Pre- engineered Rigid Frame, substantial savings can be achieved as compared with other systems.

- SAVE ON TIME AND COST OF ERECTION WORK

Components of AISSI Pre – engineered Rigid Frame are accurately shop – fabricated and assembled at site using all – bolted connections. No expensive jobsite welding and oxy – acetylene torch – cutting works. Roofing and wall cladding panels are delivered cut-to-size for quick enclosure of the building shell.

- ADAPTABLE TO VARIOUS BUILDING APPLICATIONS

Constructions of large un- obstructed floor space such as those needed for school buildings, agricultural facilities, filed offices, covered garage, temfacil, mass housing etc.

- WIDE RANGE OF CHOICES FOR BUILDING ACCESSORIES

Various choices for doors, windows, thermal insulation materials, roofing and cladding skins are available to suit your requirements.

Product Features

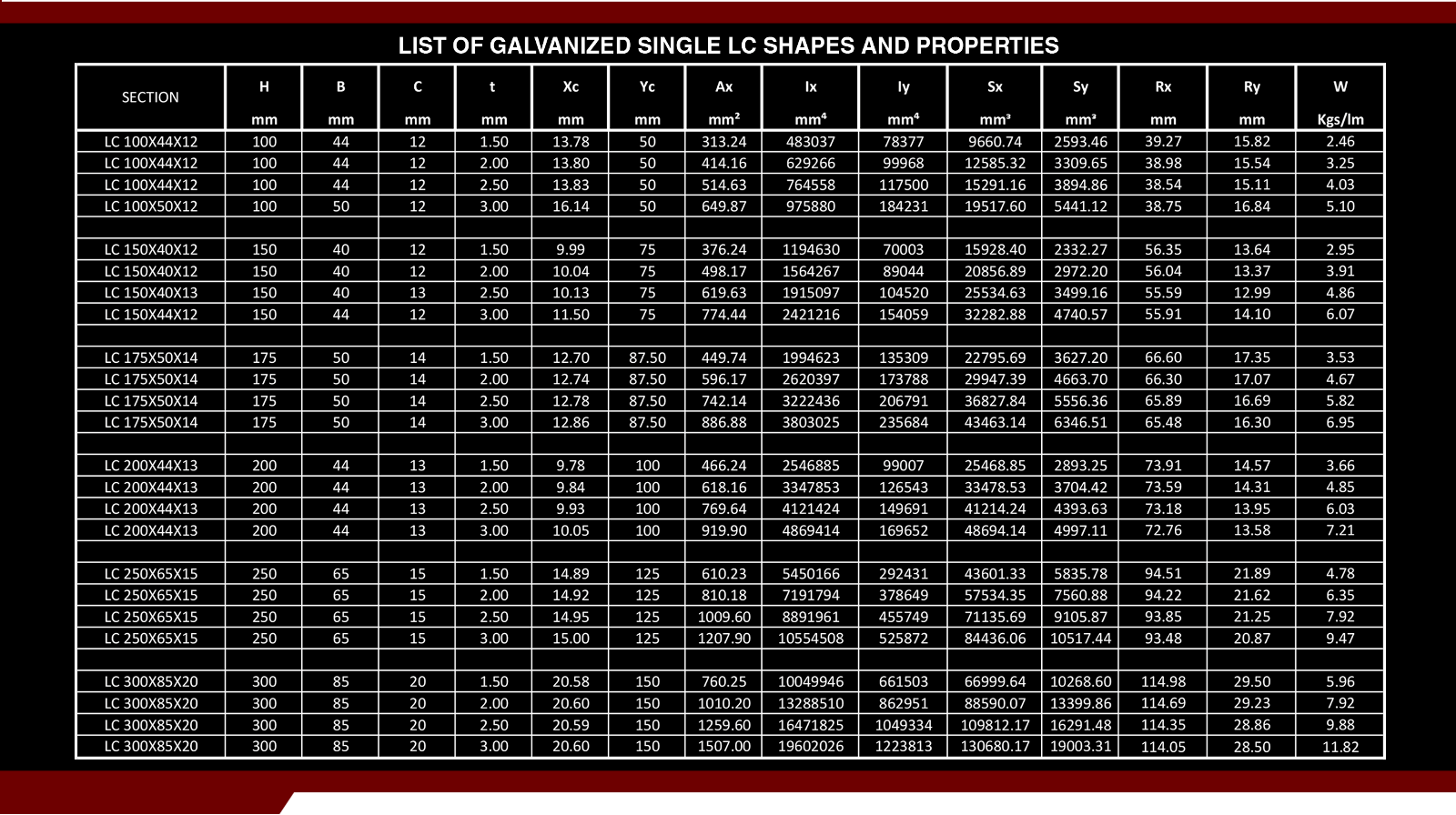

- Rollformed to various dimensions from a depth of 100mm. to 300mm.

- Available in the following thicknesses: 1.5mm.,2.0mm.,3.0mm.,3.5mm.

- Can be ordered cut to length subject to volume and transport limitations.

Advantages

- No need to paint.

- Highly compatible to use with long span pre-painted roofing materials.

- Since AISSI Hi-TEN LC Shapes can be ordered longspan, sections can be analyzed as multi-supported continuous members resulting in lower flexural stresses. Compared with simply-supported members, AISSI Hi-TEN LC Shapes are therefore safer and more economical to use.

- Unlike B.I sections, AISSI Hi-TEN LC Shapes do not have rust-staining problems.

Applications

- Can be used in residential, commercial, and industrial projects requiring hygienic and long term lifespan.

- Highly adaptable in agriculture & livestock industry such as poultry houses, piggeries, etc.

- Highly recommended to use in corrosive environments such as in food processing facilities, etc.

- Ideal to use in recreation and resort facilities exposed to salty air.

DYD Door Series

DYD Door Series

Based on the technical licence agreement and marketing distribution agreement (KOREA and JAPAN TECHNOLOGY – Exclusive distributor in the Philippines) with ‘Yong Sung Refrigeration Co., Ltd.’ in Korea and ‘Nankyoku Bounetu Co.,Ltd.’ In Japan, DYD Refrigeration Systems Inc. have manufactured and supplied the new developed compact design insulated door system by combination of new technology and new materials for various customer’s demands and requirements, which is totally different type from the ordinary doors.

Also by our own design, we are developing all doors parts to be suitable forHACCP(Hazard Analysis Critical Control Point) program assuring durability, safety, versatility, sanitation purposes. We are doing efforts to produce and supply the high quality insulated doors system with lower costs to our customers.

DYD – Insulated Door System advantages

- Preventing the doors from corrosion, the lumber entirely is not used at DYD doors.

- By using poly-urethane foam, insulation effect of door is increased

- Door is easily to open and close with the weight being 1/3 less than the ordinary door type

- The corrosion is prevented by using aluminium, anti bacterial plastic and stainless steel at surface of door, handle, and fastener parts

- The series of doors fabricated by DYD are suitable for all HACCP (Hazard Analysis Critical Control Points) regulations

- Gasket packing materials is made as SANPRENE – anti-moulds & bacterial treatment for strong oil resistant and a long self life, extreme low temperature use(up to -70 ºC), and it gives a high insulation effect by 4 times sealing structure.

DYD – Sliding Doors (Manual /Automatic, and Single / Double )

1) Application of DYD Sliding Doors :

- Available in Manual, automatic, single and double sliding doors type to be applied for various demands of gasket sealed and polyurethane insulated with variable thickness by using temperature requirements

- Good for middle and large –scale cold storages

- Various food processing industries and supermarket

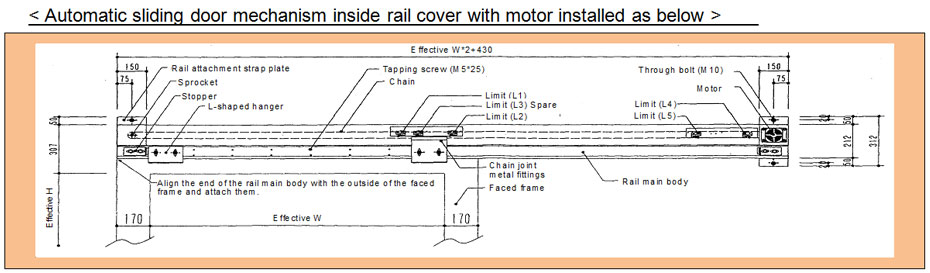

2) Sliding Mechanism :

- Door hanger sliding system for easy and gentle open/close

- Using heavy duty non-corrosive J- Aluminium rail track to minimize wear/tear of nylon roller for smooth slide.

- By using reinforced aluminium for the sliding rail materials, minimizing the abrasion with the sliding roller.

- Designed to eliminate noise and increase durability, the reinforced nylon rollers at our sliding door are used

3) PVC door jamb : Designed for thermal break, sealing tight gasket insertion/rigid structure along 3 sides

4) Aluminium gaskets holder and door heater :

- Designed for Sanprene gaskets and defrost heater insertion al.moulds along the four sides of door frame

5) DYD – Automatic Sliding doors (single / double) features:

- Adaptation of micro chip enables to control several functions automatically – door speed, torque control, door open/close(half or less), trouble shooting.

- By using the smallest AC motor (Micom control compact type, 1 phase100 Volt), strong power, high durability, and less noise at the optimum conditions. And it is installed at the relatively small area inside rail cover for HACCP.

- Operated by pull (wire rope) switch and push switch. Can be operated by photo sensors (optional) and be controlled by remote control even when on forklift operation.(optional)

- Internal lock function connected with the external systems can be functioned. (optional)

6) DYD – Sliding door Specifications

| Sliding Type | Manual / Automatic, Single/Double Sliding |

| Door Thickness (mm) | 50, 75, 100, 125, 150, 150 mm Thick Panel, polyurethane |

| Temperature of room | ( +) 15 ºC – Up to (-) 50 ºC |

| Surface Skin | 0.5 – 0.6 mm T PPGI or PPGL/0.6 mm T Stainless Steel 304 |

| Door Jamb | Extruded PVC door Jamb |

| Gasket | Sanprene gasket for exetreme temperature application |

| Lock | Gunplate safe lock |

| Door Header | 9 / 16 ohm for 4 sides door leaf, electronic temp. controller |

| Rail | Extruded Aluminum J shape rails with heavy duty rollers |

| Overlap | 60 mm overlapping on opening |

| Door Accessories | Aluminum gasket/heater holders, Plastic Handles, emergency escape, rail brackets, bottom guide roller, Rail cover, buffer device, temperature controller, Chains (auto), pull/push switch (auto), other fixing components. |

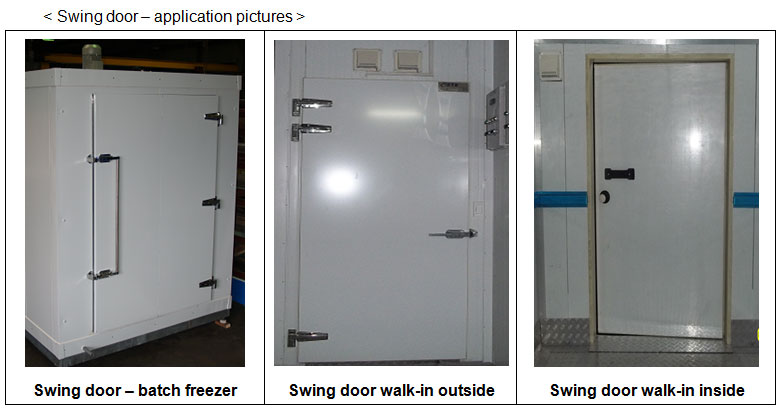

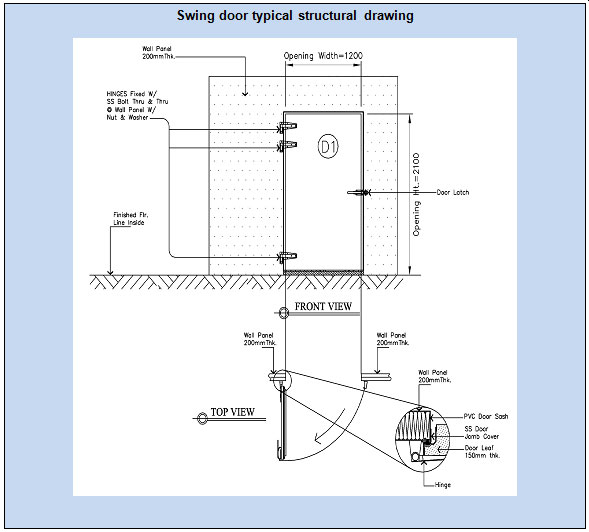

DYD – Swing Doors (Single and double swing door design)

1) Application of DYD Swing Doors

- Available in Manual single and double swing doors type to be applied for various demands of gasket sealed and polyurethane insulated with variable thickness by using temperature requirements

- Good for small scale cold room

- Walk-in chillers and freezers

2) Swing doors Mechanism

- Usual opening angle application up to 90º

- Swing Door leaf framed by PVC Z type sashes

- Swing Door Jamb framed by PVC C type sashes

- Sanprene E-type side gaskets, Sweep type bottom gasket with gasket holder to seal gap in between door leaf and door jamb

- Using heavy duty chrome plated or stainless steel door latch, hinges

- Heater – defrost heater 3 sides surrounding door jamb

- Installed safety door opening release button inside of room at the rear of door leaf

3) DYD – Swing doors Specifications

| Sliding Type | Manual, Single/Double Swing |

| Door Thickness (mm) | 50, 75, 100, 125, 150, 150 mm Thick Panel, polyurethane |

| Temperature of room | ( +) 15 ºC – Up to (-) 50 ºC |

| Surface Skin | 0.5 – 0.6 mm T PPGI or PPGL/Stainless Steel 304 |

| Door Jamb | Extruded PVC door Jamb |

| Gasket | Sanprene e-type gaskets and sweep type bottom gasket with gasket holder for extreme temperature application |

| Lock | Overlap latch(chrome plated or stainless steel) |

| Door Header | 9 / 16 ohm for 4 sides door jamb |

| Overlap | 35 mm overlapping on opening, sweep overlap on bottom |

| Door Accessories | Latch, Hinge, Handle, safety release button, other fixing components. |

DYD- Vertical up/down Door-automatic /manual, single / Split type

1) Vertical up/down Door features (Based on KOREA / JAPAN TECHNOLOGY)

- Good for warehouses when there is no area on the sides or for automatic line storages

- Less overload for opening, by balancing in between door and balancer to be connected by chain

- This door can be easily stopped when opening manually.

- When operated automatically, it is to be opened and closed with the conveyer

2) DYD – Vertical up/down doors Specifications

| Vertical Door Type | Manual/automatic, Single/Split, ½ level |

| Door Thickness (mm) | 50, 75, 100, 125, 150, 150 mm Thick Panel, polyurethane |

| Temperature of room | ( +) 15 ºC – Up to (-) 50 ºC |

| Surface skin | 0.5 – 0.6 mm T PPGI or PPGL/Stainless Steel 304 |

| Door Jamb | Extruded stainless or aluminum door Jamb |

| Door Heater | Separate circuit wiring from the motor line |

| Effective size | 2,500 mm W X 2,500 mm H, other size will be specified |

| Door Accessories | Chain, balancer, motor (auto), handle, fixing components |

DYD – Manual Heavy Duty Overlap Door- manual single/double

1) Heavy Duty overlap Door features (Based on KOREA /JAPAN TECHNOLOGY)

- Good for small cold storage

- Maximum door opening degree : 90 to 180º

- Single and double opening overlap doors also available

| Overlap Door Type | Manual, Single/Double |

| Door Thickness (mm) | 50, 75, 100, 125, 150, 150 mm Thick Panel, polyurethane |

| Temperature of room | ( +) 15 ºC – Up to (-) 50 ºC |

| Surface skin | 0.5 – 0.6 mm T PPGI or PPGL/Stainless Steel 304 |

| Door Jamb | Extruded PVC/stainless/aluminum door Jamb |

| Door Heater | 4 sides Door Leaf circuit wiring, middle (double) |

| Gasket | Sanprene gaskets at 3 sides, centre (double, half round), bottom |

| Effective size | 1,800 mm W X 4,000 mm H (single),

4,500 mm W X 4,500 mm H(double), other sizes will be specified |

| Door Accessories | Heavy duty hinges, gun-plate safe lock, plastic handle, aluminum gasket/heater holder, temperature controller, fixing components. |

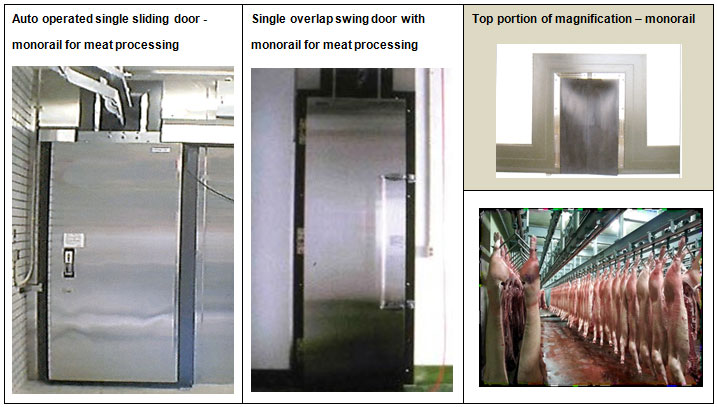

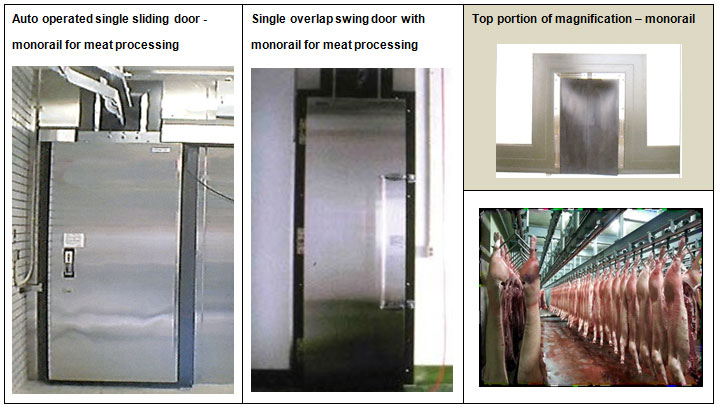

DYD – Monorail Overlap Door – single sliding and overlap swing

- Ideal application for slaughter houses and cutting & deboning plant

- Vinyl chloride sheets equipped at the upper part of monorail

- Based on KOREA / JAPAN TECHNOLOGY

DYD – Flip-Flop Door (Based on KOREA TECHNOLOGY)

- Maximum door opening degree : 180 º, Wider view by view glass, single / double type

- Application for inside cold storage, food processing plants

- Rubber Spring bumper absorbs hitting shock

- Tight seal protecting gasket, Heavy duty floor mounted hinges

- Poly-Urethane foam inside material for effective insulation

DYD – Air blower shutter – side horizontal air flow circulation (based on Korea Technology)

- Double blocking cold air from sinking to the bottom, Blocking heat from entering from the top

- Up to 30~50% energy cost saving than top to the bottom type air curtain

- Pre-filter at best of the opening always allowing clean air to flow in

- Optimum control by of the wings on opening

- Minimizing cool air leaking by using gaskets

DYD – Air blower Curtain – Vertical air flow

- Blocking cool air and energy saving

- Insect resistant

- Blocking dust and odor inlet

- Increasing sales and stability

DYD – Vinyl sheet Curtain Doors, Strip Curtain door

- Easy and economic installation, Saving energy costs

- Effective insulation of temperature, anti-insect, blocking noise and wind

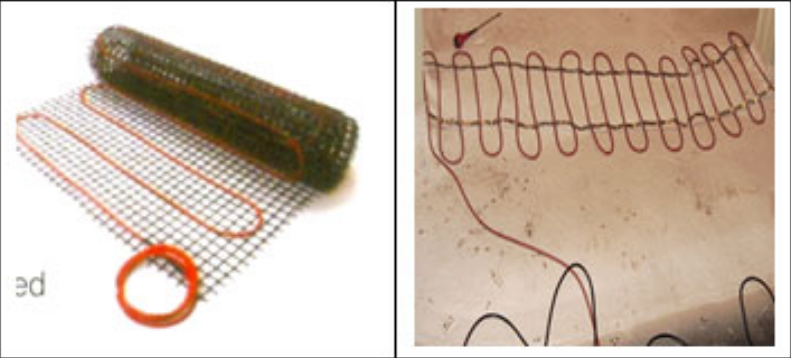

DYD – Floor Heater (underneath Doors along opening line)

- Avoiding Ice Built Up underneath Doors

- Fast and transferring heat to the floor

- Easy installation, small space required, 500 mm W X 2,500 mm, spacing with plastic nets

- Long self-life,

- 500 W electric consumption – self heating

DYD – Air Tight Door (Clean Room, manual/auto, single/double sliding)

1) Air tight door features (based on KOREA / JAPAN TECNOLOGY)

- Application for clean rooms to be suitable for HACCP – Food processing plants, electronic semi conduct industry, Pharmaceutical industry, Hatchery farms, Hospitals

- Achieved A-4 level for sealing tightness.(Japan’s Nankyoku Bounetsu Co., Ltd.)

- By using poly-urethane foam, making it light weight with high durability, insulation and moisture prevention functions, equipped with viewing glasses

- Non contact sensors allow the doors to be opened more easily so it can be maintained under cleanness condition. Sensor type safety switches or tap switches be equipped.

- Manual opening is smooth. Also, it can be maintained under cleanness condition because automatically closing after being opened.

- For safety, the air brake is activated when the door is closed automatically and is to reduce the door closing speed to be lessened shock when collided.

| Measurement | Pressure difference(Pa) | Ventilation Volume (m3/h.32) | |

| Single | Double | ||

| 10 | 0.09 | 0.13 | |

| 30 | 0.18 | 0.26 | |

| 50 | 0.29 | 0.37 | |

| 100 | 0.91 | 0.6 | |

| Air tight door Type | Manual /Auto, Single/Double sliding | |

| Effective Size | Single sliding ; 600 – 2,000 mm W X 3,000H X 42 mmT

Double Sliding ; 1,200 – 4,000 mm W X 3,000H X 42mmT |

|

| Door Leaf | Surface | PPGI or PPGL or Stainless steel 304 |

| Leaf Frame | Aluminum alloy extruded materials | |

| Inside | Polystyrene foam | |

| Rubber | Rigid poly chloride | |

| Handle | Anti bacterial resin (inner aluminum substitute added) | |

| Guide Roller | Stainless steel 304 | |

| Door Jamb | 3 Side Frame | Aluminum alloy extruded materials |

| Gaskets | Rigid poly chloride | |

| Drive Function | 4 sides Door Leaf Circuit wiring, middle (double) | |

| Options | Window | Acrylic board 5 T/Glass (attached shatter proof film) |

| Window Frame | Aluminum alloy extruded materials | |

| Reduction Gear | Cylinder | |

| Safety fixture | Sensor switch / tap switch | |

DYD –Fireproof Doors and Marine Fireproof Heat Shielding Door (Manual/auto – single/double sliding, overlap based on KOREA/JAPAN TECHNOLOGY)

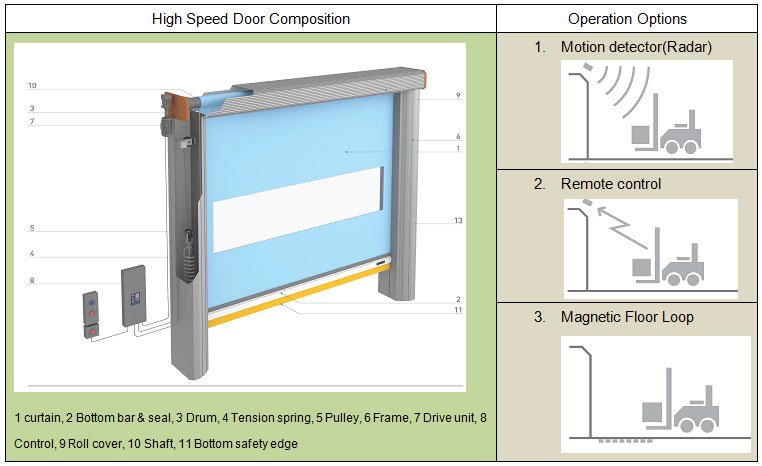

DYD – High Speed Door (Automatic)

The high speed door is based on KOREA TECHNOLOGY and is capable of rapid and smooth operation with a highly durable curtain fabric, spring counter balance system, a high-performance electric drive unit, and an inverter-equipped controller with various sensors. It is the economical and efficient automatic door with safety devices and convenient functions.

1) DYD – High Speed Door applications

Logistic centres,Cold storages, Food processing plants,

DYD – High Speed Door Features ;

DYD – high speed consists of a durable fabric sheet, aluminium frame, a rapid operator, a counter balance system, and various safety devices.

- Materials : THK2.5 fabric(polyester sheet + acrylic coating)

- Counter balance : Tension spring balance

- Door speed : Opening – 1.5 to 2.5m/s, Closing – 0.5 to 1.5m/s

- Wind pressure : Inside 20 to 28m/s

- Temperature : Applicable (-)35 ºC to (+) 85 ºC

- Maximum size : Available range – up to 6,000 mm W X 6,000 mm H

- No surface temperature increase where the fire is flamed to 1000 Celsius degree, realizing very high fireproof and preventing freezing because of the heater inserted inside gasket packing. (Certificate Nos. in Japan ; EA-0155-6 for Special fireproof and CAT-0348-9 For Danger preventive provisions of single/double sliding doors)

- Door is covered by fireproof materials of Silicate calcium board With PU insulation foam, door frame is made of silicate calcium board lined with stainless steel sheet

- 30% lighter weight compared with other fireproof door makers, so easy and smooth opening/closing can be done without vibration. And the durability of all using parts are improved for a long self-life.

- Equipped with the emergency escape device which enables. people to open from inside room, in case of door open/close switch malfunctioned.

DYD Panel Application

DYD Panel Application

- Various Cold storages for meats, fishes, fruits, vegetables, ice, further processed food and meat products, chemicals,

- Chicken dressing plants, pig & cattle slaughter houses, dairy and milk processing plants, fisheries & sea-foods processing plants, further meat processing plants, various beverage processing plants,

- Wet- markets and food terminals

- Agricultural poultry houses & Hatcheries, Piggery houses & Boar houses

- Commercial walk in freezers and chillers for shopping mall, super & hyper market, Hotel & restaurants, Institutional school, Military and Factory canteens

- Blast freezers and chillers

- Various IQF freezers

- Refrigerated trucks, vans and fishing troll boats

- Clean room and air conditioning rooms for Pharmaceutical, Semi-conduct industries

- Telecommunication cell site cabins

Food Processing

Food Processing

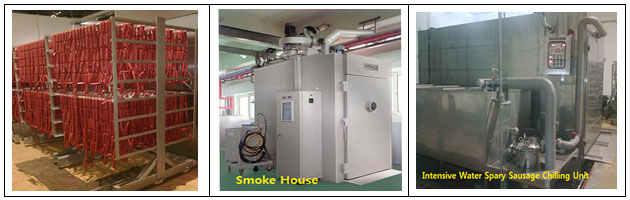

Ham & Sausages Processing line flow and equipments

Process: Raw materials → Curing at cooling storage→ Grinding → Vacuum Bowl cutting→ Vacuum stuffing → Smoking→ Intensive water spray cooling→ Staging at Cooling room → Vacuum Packaging→ Boxing

Nuggets & Hamburger Patties line flow and equipments

Process: Forming→ Predusting→ Battering → Breading→ Frying → Air tunnel cooling→ Spiral Freezing→ Vacuum Packaging→ Boxing

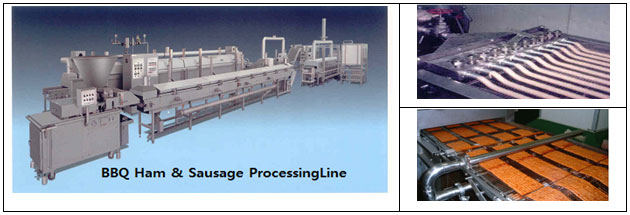

Barbeque Ham & Skinless sausage line flow and equipments

Process: Vacuum stuffing→ Forming nozzle→ Super-oven cooking → Colouring→ Steaming→ Air tunnel cooling (cascade)→ staging at Cooling room→ Vacuum Packaging→ Boxing

Corned Beef Cooker line flow and equipments

Process: Frozen meat blocks → Defrosting→ Pre-cutting → Vacuum tumbling→ Curing at cooling room → Hot Kneader – Double jacket agitating cooker→Shredding→ Canning→ Retorting→ Boxing

Various meat processing preparation and canning equipments

Equipments: Frozen Block Flaker, Meat Grinder, Vacuum Mixer, Pickle Injector, Vacuum Tumbler, Vacuum stuffer, Various Former for hamburger, nuggets, Retort for can & Pouches

IQF Freezing System

IQF Freezing System

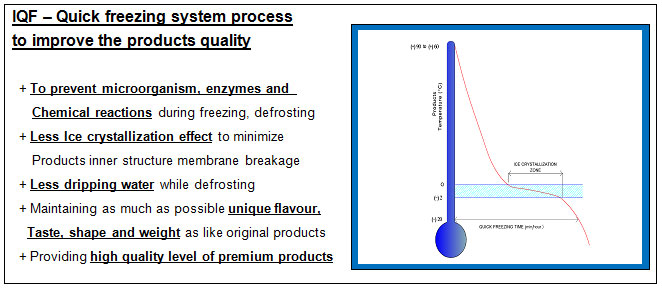

DYD – IQF Freezing System Outline

DYD – IQF Freezers – Tunnel Freezer, Spiral freezer and batch quick freezer are based on KOREA TECHNOLOGY and the most ideal way of food preservation and distribution for IQF (Individual Quick Freezing) products. And these freezers are effectively used and applied for various chilled & frozen products processing. These freezers are suitable for all production lines, single and multiple, increasing productivity as well as saving energy and labour costs, and satisfying consumer demands.

The advantages to use DYD-IQF Freezing systems ;

- The fast/quick cooling and freezing time will be accomplished within 10 to 60 minute compared with 6 to 8 hours the conventional blast freezing (slow freezing)

- Flexible application for the continuous production line in combination with pre and post processing lines such as steamer, baker, fryer, boiling and various packaging

- Fully automated production line increases the productivity by 60 % more.

- Tremendous labour saving, running cost down, easy maintenance & cleaning for HACCP foods safe program which could not be achieved from the ordinary freezers. The premium quality of products will be provided to the processors as shown below

DYD – IQF Freezing System Applications

Chilled & frozen food products wide range of Raw food materials and processed products ;

- Aquatic products – crab, squids, shrimp, tuna, mackerels, various fisheries etc.

- Various Cooked and Fried products – Chicken nuggets, Hamburger patties, fried fishes, Meat ball, Imitate crabs, fired shrimp etc. frozen products after cooking and frying

- Meat products – Pork, Beef, Chicken, and other meats

- Dumplings and Noodles – Dumplings, Siomai, Siopao, Spring rolls, Wanton, Spaghettis, Noodles

- Breading powders, Croquettes, Pizza pies, Snacks, Fish jellies, Pudding, Desserts, etc.

- Fruits products – Banana, Pineapple, Mango other Fruits

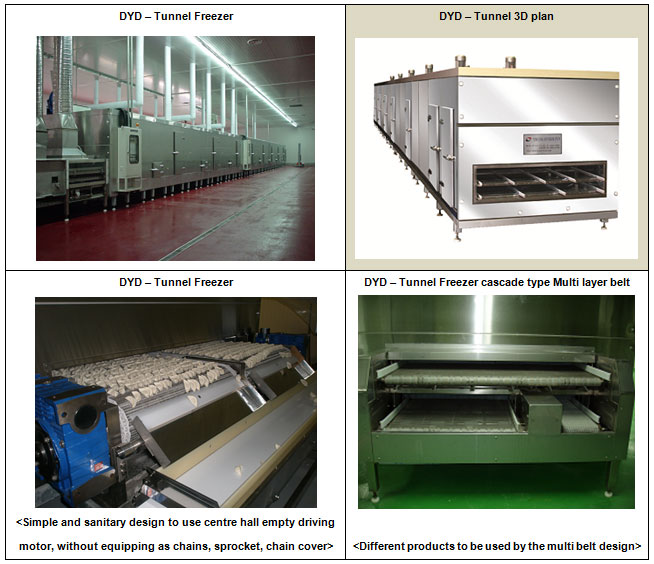

DYD – IQF Freezing ‘Tunnel Freezer’

Features:

- FAN MOTOR is mounted on the outside of the freezer (Patented) : by reducing heat created from motor, loading capacity of compressor on freezer will be minimized.

- Efficient and sanitary system to be suitable for HACCP, Freshness Quality Control System for quick freezing.

- Effective systems through compact and simple design, reducing labour, operating costs

- Strong, rigid belt design, Mesh and flat belt used for sanitation (stainless steel, Plastic)

- Flexibly used with steamer, oven, fryer, boiler – all kinds of food manufacturing lines.

- The differential pressure created by turbo fan, providing unique circulation of air flow.

- Total automatic production line by automatic control system with built in inverter.

- The extended continuous production time without down time of defrosting interval period is achievable by ADF (automatic De-Frost) system as option (Patented).

Specification:

| Model | DTF-250 | DTF-500 | DTF-750 | DTF-1000 |

| Capacity | 250kg/h | 500kg/h | 750kg/h | 1000kg/h |

| Dimension (mm) | 2,800 W | 2,800 W | 2,800 W | 3,400 W |

| 12,000 L | 18,000 L | 20,000 L | 23,000 L | |

| 2,200 H | 2,200 H | 2,200 H | 2,200 H | |

| Cooling fan motor | 5 hp X 4 | 5 hp X 8 | 5 hp X 12 | 5 hp X14 |

| Compressors(60hz) | 37-55 kw | 37-92 kw | 55-165 kw | 110-220 kw |

| Drive Motor | 3 ph, 220 V , 0.5 kw – 2.2 kw | |||

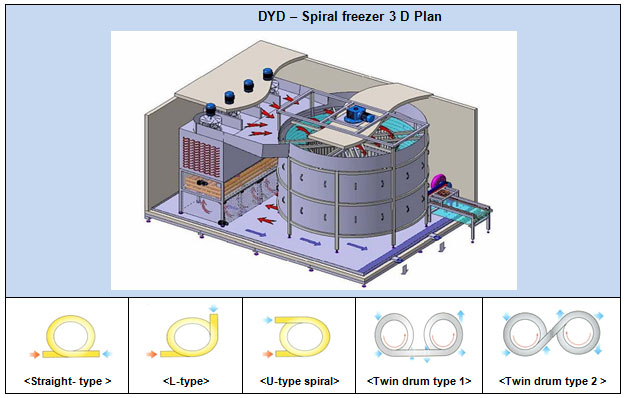

DYD – IQF Freezing ‘Spiral Freezer’

Features:

- Spiral Freezer can be installed at the limited area by the compact type design and unit module type design.

- Flexible design for input and output direction (straight type, L-type, U-type shape)

- Wide range of applications(cooling, drying, steaming, freezing spiral system)

- Strong, rigid belt design, Mesh and flat belt used for sanitation (stainless steel, Plastic)

- The extended continuous production time without down time of defrosting interval period is achievable by ADF (automatic De-Frost) system as option (Patented).

- FAN MOTOR is mounted on the outside of the freezer (Patented) : by reducing heat created from motor, loading capacity of compressor on freezer will be minimized.

- Automatic control system by inverter and PLC built –in

- CIP (Clean-in-place) system are available for belt and inside chamber cleaning (details as specified by option of customer design)

| Model | DSF-250 | DSF-500 | DSF-750 | DSF-1000 |

| Capacity | 250kg/h | 500kg/h | 750kg/h | 1000kg/h |

| Dimension (mm) | 4,500 W | 4,500 W | 5,200 W | 5,200 W |

| 6,000 L | 6,800 L | 7,500 L | 8,000 L | |

| 2,700 H | 3,300 H | 4,000 H | 4,700 H | |

| Cooling fan motor | 5 hp X 4 | 5 hp X 3 | 5 hp X 4 | 5 hp X 5 |

| Compressors(60hz) | 37-55 kw | 57-92 kw | 92-110 kw | 110-165 kw |

| 508 wide | 609 wide | |||

| Drive Motor | 3 ph, 220 V , 0.5 kw – 2.2 kw | |||

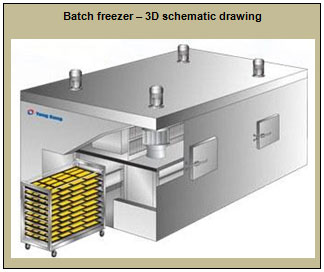

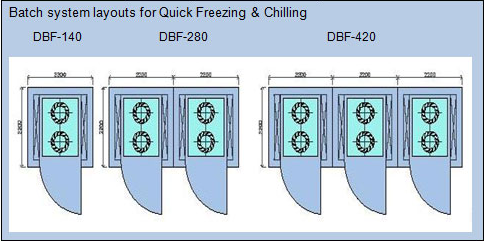

DYD – IQF Freezing ‘Batch type Quick Freezer’

- By using trolley carts, suitable application to various products for small production

- Without process stop, it is connected in between pre-processing and post-processing.

- Quick freezing by strong air circulation (Down flow design) of Axial fan

- Using inverter controller, air speed is controlled variably for producing various products.

- In case of adapting a complete condensing unit, no necessary separated machine room.

- By using trolley carts, after freezing process the trolley carts can be stored inside room

Specifications:

| Model | |||

| Capacity | 140kg/h | 280kg/h | 420kg/h |

| Dimension (mm) | 2,200 W | 2,200 W | 2,200 W |

| 2,200 L | 4,400 L | 6,600 L | |

| 3,100 H | 3,100 H | 3,100 H | |

| Cooling fan motor | 5 hp x 2 | 5hp x 4 | 5hp x 6 |

| Compressors(60hz) | 22 kw | 37 kw | 55kw |

Loading Bay Equipments

Loading Bay Equipments

- DYD – Sectional Door(manual / auto)

- size : 13m W X 8 m H

- Panel Thickness : 50 mm T PU,

- Panel pitch : 530/610mm

- Viewing glass equipped

- DYD – Dock Leveller (Hydraulic operated/ Manual)Size – 2.0 m W X 2.5 m L X 600mm H

- DYD – Dock Seal

- Small : 1.6m W X 2.2m H

- Big : 2.3 m W X 2.7 m H

- DYD – Dock Shelter

- Standard size ; for 40ft container3450mm W x 3600mm H X 600mm D

- DYD – Air Inflatable Dock Shelter

- Standard size ; for 40ft container3600mm W x 3555mm H X 770mm D

- Air bag pump : 180W

- DYD – Dock Rubber Bumper

- Size : 250 W X 500L X 125mm D

Pig & Cattle Slaughtering Lines

Pig & Cattle Slaughtering Lines

Capacity : 100~600 pigs/hr. ( Custom made)

Dimension: 2400W x 2230Lx3400H

Electric Power: 5.5kW x 380V (or 440V)x3P

Material: all Stainless Steel( Except for the drive Series )

Included Equipment: Sliding Chute

Capacity : 100~600 pigs/hr. ( Custom made)

Dimension: 2400W x 2230Lx3400H

Electric Power: 5.5kW x 380V (or 440V)x3P

Material: all Stainless Steel( Except for the drive Series )

Included Equipment: Sliding Chute

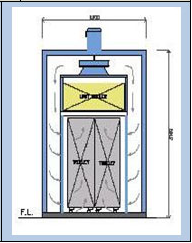

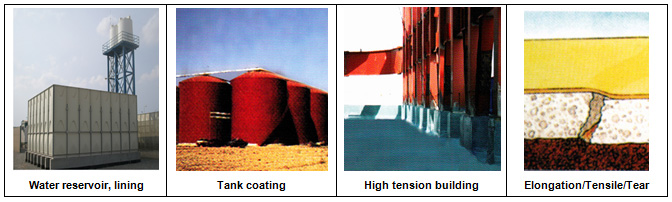

Polyurethane Spay Foam

Polyurethane Spay Foam

- Seamless monolithic insulation system

- Very low water absorption – Stable strong cellular structure of rigid P.U foam locks out water penetration

- Dual effects for Insulation and waterproofing – ideal application of metal & concrete roof deck

- Ideal for flashing at parapet

- Possible inside spray under roof or truss / outside spray on the top of roof for new and repair works

- Various application for insulated tanks – Beer tank, Accumulator, Grain silos, water tank

- Wide range of building roof water proofing by repair and new, and animal (livestock) houses

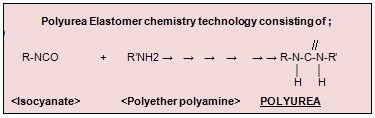

DYD – Polyurea Coating Outline and Application

- Reaction of isocyanate with primary amine Terminated polyesthers.

- Process is high pressure, high temperatureImpingement mix spray equipment

- Two component spray elastomeric and coating

- Mixing index : Isocyanate 0.5 kg + Resin 0.5 kg = 1 m2

| Properties | Tensile Strength | Elongation at break | Yield Strength | CLTE |

| Value | 130-200 kgf/cm2 | 200-500% | 800-1800 kgf/cm2 | 13.4 X 10-5/ ºC |

Refrigiration & Air conditioning Equipments

Refrigiration & Air conditioning Equipments

- Hermetic scroll compressor equipped

- Hermetic reciprocating compressor equipped

- Semi-hermetic reciprocating compressor single stage

- Semi-hermetic reciprocating compressor 2-stage

- Semi-hermetic screw compressor (inverter type as option)

Water-cooled condensing unit

as same as air-cooled condensing unit compressor equipped

Air-cooled condensers

Air-cooled fin & tube package, Air-cooled fin & tube (U, H, L, C, V type)

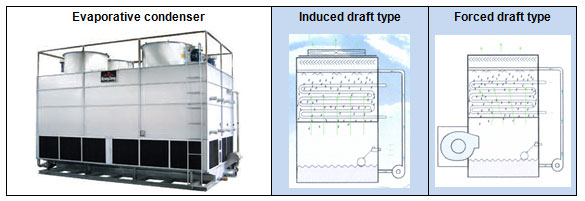

Evaporative condensers (Evacon – water and air combination cooling)

- Maximized condensing capacity, CE certificate products

- Compact design by seamless pipe and high strength steel(STPG410) and enhancing high cooling efficiency

- Induced draft type and Forced draft type are available depending on application

Unit coolers – electric / water defrosting

Ceiling hanger type, Slim type – middle of ceiling mount, Overhead mount type, Floor type

Other Refrigeration components

Oil separator, Receiver, Accumulator, Shell & tube water chillers, Plate heat exchanger and so on to be supplied and installed by the customer’s design

Joint Venture

Joint Venture